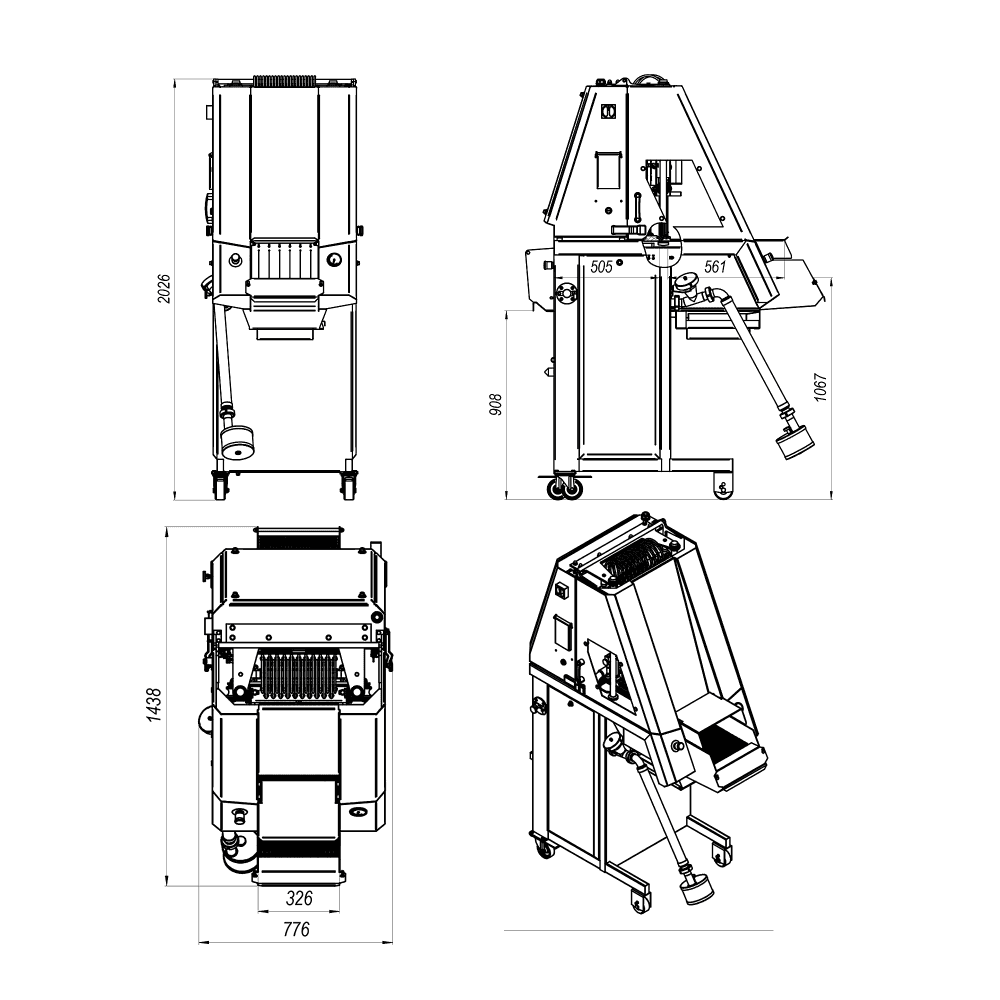

Nowicki Automatic Meat Injector – MHM-39

External Dimensions (WxDxH) see diagram

Throughput 500-1000kg/h (depending on product)

Working Width 375mm

Working Height 160mm

Number of needles 39 (single needle) 78 (double needle)

Conveyor Belt Speed 16, 36 or 75mm/cycle (adjustable)

Stroke of Injection Head 20,21,22…..40 strokes/min

Electrics 3ph 400V 50Hz 2.4kW

Weight 430kg

Price on request

Designed for brine injection of meat, with bone or boneless, meat products, whole

Poultry and poultry parts, fish and fish fillets.

Advantages:

low and high injection levels

Smooth regulation of the speed of the head and the conveyor as standard (in the MHM 21 model – optional)

Intuitive touch screen control panel

Uniform distribution of brine

highly efficient centrifugal brine pump made of stainless steel

smooth brine pressure control

function of mixing and pumping out the brine from the tank (for the FBN rotary filter)

helical pump for heavy brine (optional)

closed brine circulation system

easy to clean multistage brine filtration system

Injection head:

low and high injection levels

system of multifunctional injection heads (2, 3 and 4-needle depending on the model) replaceable injection head with the possibility of quick assembly and disassembly

each head can be equipped independently with the required needles selected from the catalogue of needles or on request a unique needle can be designed for special products