Nowicki KN200 Cutter

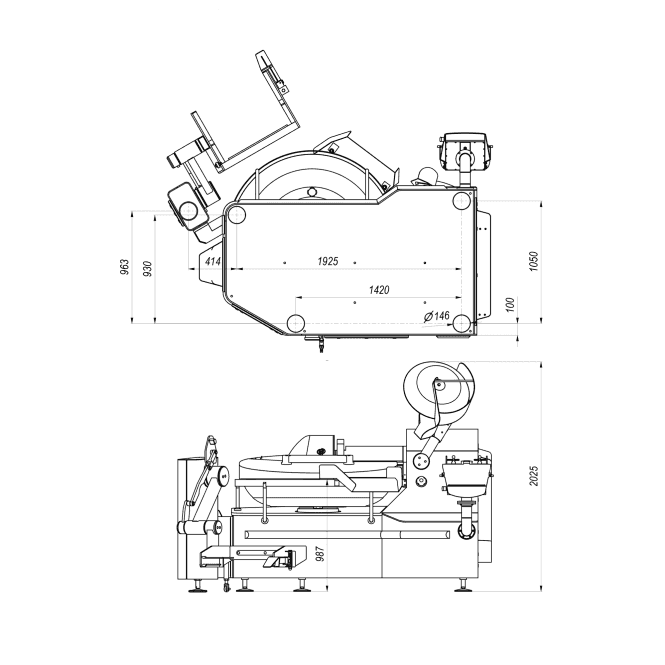

- External Dimensions (WxDxH) See diagram

- Power 3ph 87.5kW

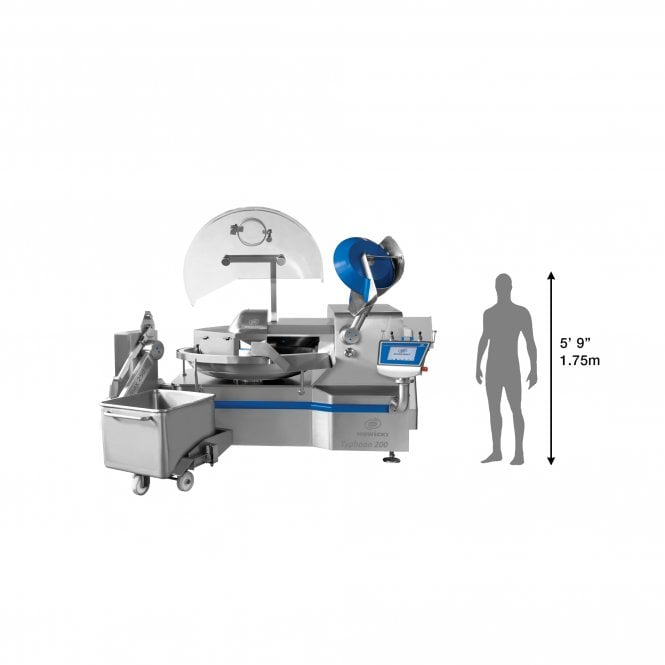

- Volume 200 litre

- Capacity 60-170kg product (depending on product type)

- Knife Speed Variable between 100 to 4800rpm

- Mixing Speed Variable between 100 to 300rpm

- Bowl Speed Variable between 2 to 20rpm

- Digital Thermometer included

- Control Panel Touch panel with joysticks to control covers, loader & unloader

- Weight 3400kg machine & 300kg control panel

Optional extras:

- Additional knife sets

- Auto water dosage

- SCADA monitoring system with industrial computer

- Outside ventilation system

- Air conditioning system for electric box (in case of humidity or temp over 20’C)

- Remote drive for master switch (recommended when electric box is located in another room)

- Additional cabling over 5m with st/st cover

Price on request

Features

- stainless steel construction

- high quality and repeatability of stuffing production

- optimal shape of the cutting chamber in combination with the shape of the knives

- equal stuff crumbling in all the bowl’s volume caused by “cutting in the air”

- high-speed rotations of knife head (cutting rotations)

- microprocessor control system

- smooth control of cutting and mixing rotations as a standard

- possibility of programming up to 40 technological programs

- automatic water dosage system

- effective noise insulation cover

- head with cutting knives not requiring regulation of distance from bowl

- stuffing temperature control

- automatic central lubrication system

- possibility to install a higher power motor for heavy stuffing production

- hydraulic loading to production trolleys 200 l

- easy unloading with the stuffing unloader controlled by a joystick

- hydraulically operated front and back covers of the bowl

- monitoring system of the current machine operation, auto diagnostic and sound signaling system

- construction meets the highest hygiene requirements (flat surfaces inclined at an angle of 3 degrees)

- product contact surfaces are polished

- complete work safety system